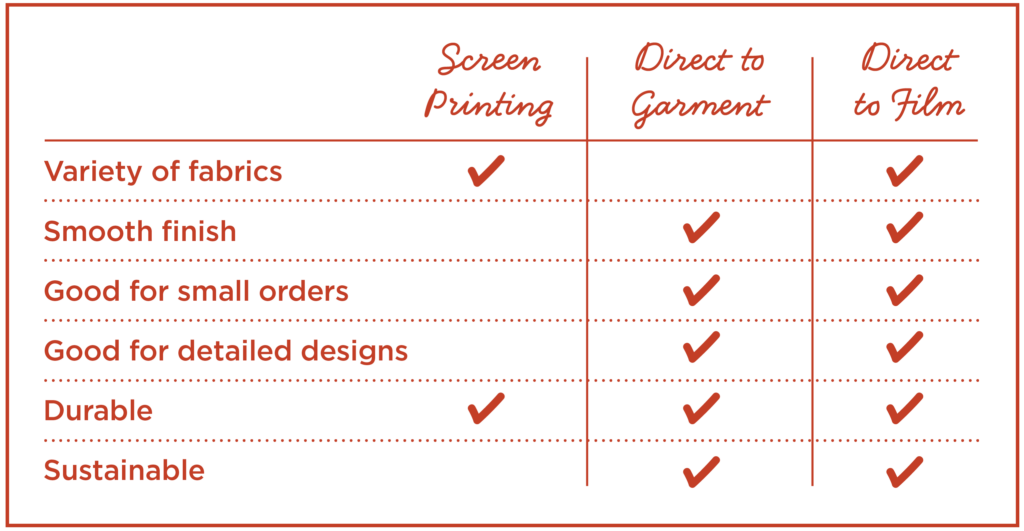

When it comes to your custom, branded apparel, you have a choice in how you want your items printed. Each has pros and cons. The best option largely depends on your garment fabric, the complexity of your design, and the size of your order.

Let’s break down the three main printing options: screen printing, direct to garment, and direct to film.

How screen printing works

In the screen printing method, the ink is pushed through a woven or mesh screen and onto the fabric. The ink doesn’t soak into the fabric, but instead lays on top of it.

Screen printing requires more set up because a screen (think of it like a stencil) is made for each piece of your design. The colors and elements of the design are then layered on the garment. This is why a more detailed design takes longer and feels thicker; it has more layers.

The setup time means screen printing is best for bulk orders. It’s simply not cost effective to spend hours creating a screen for a couple of T-shirts.

For screen printing, stick to solid graphics. Avoid intricate designs with a lot of small details as they are hard to reproduce as a stencil. Also, you’ll be limited in the number of colors you can use.

Screen printed garments – when properly cared for – are durable, and the designs are long lasting. [Pro tip: turn them inside out before washing and don’t wash them in hot water.]

For more tips on how to extend the life of your custom printed apparel, check out this blog post.

Screen printing uses a lot of water, and the ink isn’t biodegradable, so keep that in mind if you’re concerned about sustainability.

How direct to garment or DTG printing works

In direct to garment printing, the machine sprays water-based ink onto the garment where it soaks into the fibers. Think of this method as printing ink onto a sheet of paper. Detailed designs and colorful patterns print beautifully with the DTG method.

DTG works best on 100% cotton, but cotton blends work well too. And, when cared for properly, the designs stay vibrant and last a long time. Because the ink is applied directly to the garment, it has a soft, smooth finish.

One of the big benefits of DTG is that it requires little setup. That means it’s a cost-effective choice if you’re offering print on demand or have a small number of items. And it’s more sustainable because printers avoid overproduction and product waste.

How direct to film or DTF printing works

A big advantage of DTF is that you can print on any fabric – cotton, nylon, polyester, spandex, etc. It also works well for items like hats and tote bags. It is important to note DTF can’t print images with special effects like fading, shadows or 3D.